Flue Gasi Desulfurization

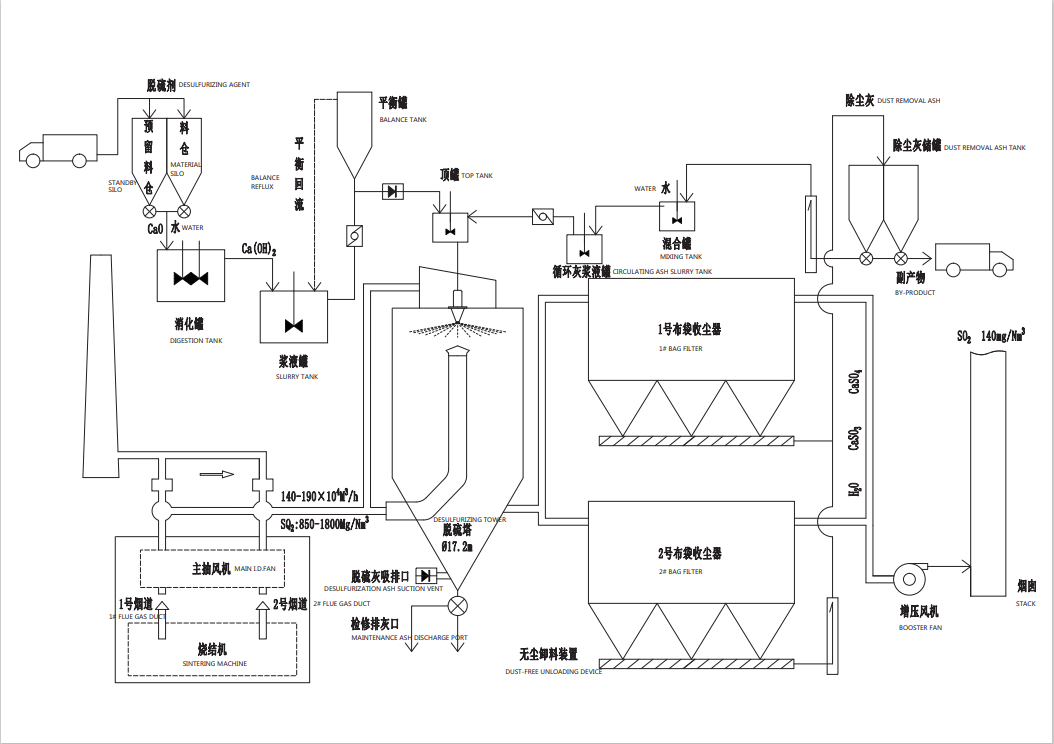

Sumo pfupi yeSemi-yakaoma Desulfurization Tekinoroji yeSintering Furnace Flue Gasi muIron neSimbi Indasitiri.

Muna 1986, Wuxi Linzhou Drying Equipment Co., Ltd, ichishandisa tekinoroji yakakura yekuomesa, yakabatana neSouthwest Electric Power Design Institute, Nanjing Institute of Forestry & Chemical Industry, Chongqing University nemamwe masangano ekutsvagisa sainzi, vakatora musoro unokosha we "Ongororo pamusoro pepamusoro sarufa marasha ekutenderera kupfapfaidza semi-yakaomeswa yedesarufa tekinoroji munyika yemakore mashanu" purojekiti yekutsvagisa.Mushure memakore akati wandei ekutsvagisa, seti yakakwana yemidziyo yemhando yeChinese yakamiswa muSichuan Baima Power Plant uye ma indexes ehunyanzvi akafanotemerwa akapedzwa zvizere, zvichiita kuti iyi desulfurization tekinoroji tsvakiridzo ive nhanho huru yekushandiswa kwemaindasitiri. Nyaya yakapfuura ongororo yehunyanzvi yakarongwa neHurumende Dhipatimendi reMagetsi muna 1990 ndokuhwina mubairo wechipiri weState Research Scientific Award.

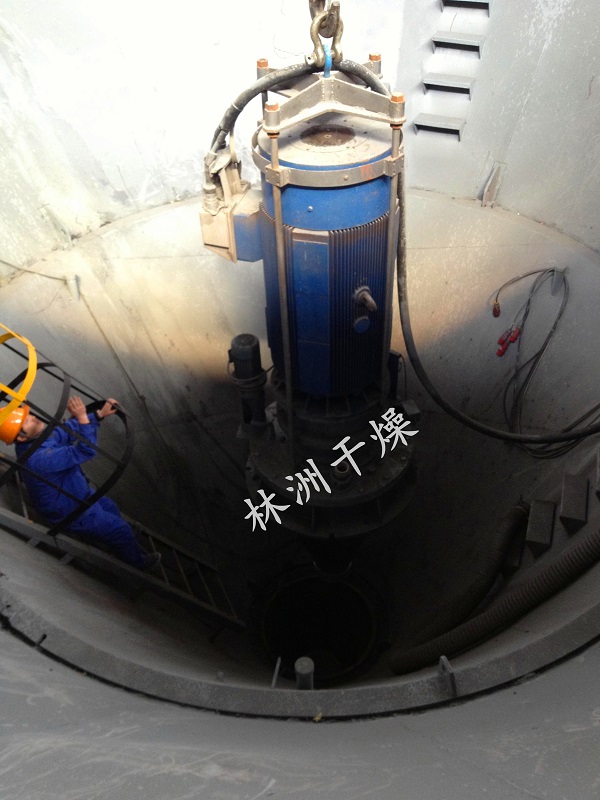

Muna 1998, semi-yakaoma flue gasi desulfurization tekinoroji yakanyorwa seimwe yezviri mukati menzvimbo. Wuxi linzhou drying equipment co., Ltd, yakabatana neSouthwest electric power design Institute, Nanjing Institute of Forestry and Chemical industry, Chongqing yunivhesiti nemamwe masangano ekutsvagisa sainzi, vakaita chirongwa che "industrial test and research yesemi-dry flue gas desulfurization equipment". nhamba yekondirakiti yaive SPKJ005-02 uye nhamba yekodhi yepurojekiti yaive j-16ikj98. Iyo yakarapwa flue gas volume i400,000 Nm3/h.Wuxi linzhou drying equipment co., ltd. inonyanya kukoshesa zvikamu zvikuru zvepurojekiti: high-speed centrifugal atomizing unit ine 45 tons yemvura yakapfapfaidza paawa.Mushure mekubudirira kwekugadzirwa kwekuedza, yakaiswa mukushanda muGuizhou Chuanheng Chemical Co., Ltd. muna 2005. Injini yekubatsira ine simba re312KW uye yakanyanya kupfapfaidza volume / h.50 t. Midziyo inoshanda pahuwandu hwakazara gore rose nekugadzirwa kwehupfu hwakaoma hwezuva nezuva hwematani 600. Kusvikira ikozvino, akawanda masheti ezvikwata akaiswa mukushanda mumunda wemakemikari makuru emakemikari. Iwo mayunitsi anoshanda nguva dzose gore rose nekuita kwakagadzikana uye kugadzikana kwemidziyo yakavimbika.

Ipo iyo 45T/h centrifugal atomizing unit iri kugadzirwa uye kugadzirwa, boka rekutsvagisa nekusimudzira rakaitawo tsvakiridzo pamusoro pemagadzirirwo eiyo semi-dry desulfurization tower, ongororo yemunda wekuyerera mushongwe yedesulfurization uye chikamu chechikamu. Chikwata chetsvakiridzo nekusimudzira chakarongwawo kuyera nekuongorora midziyo inounzwa kubva kuDenmark's NIRO Company, uye yakaunza akakodzera esoftware matekinoroji ekugadzirwa kwemhepo inopisa uye desulfurization tower yeNIRO Company.Akatora chikamu mukubhidha kwe125MW mauniti muZhejiang Qian Qing00M Power Plant muXiaoo Plant Power Plant ne1 semi-dry desulfurization mapurojekiti. Tichitarisa kubva kumamiriro ekubhidha, ane mabhenefiti makuru mumutengo, asi akarambwa nekuda kwekushaikwa kwekuita kwekutengesa. Naizvozvo, kwemakore mazhinji, mazhinji emasemi-dry desulfurization maitiro anoshandiswa mudzimba magetsi emagetsi anounzwa kunze midziyo kubva kunze kwenyika.

Mumakore achangopfuura, nekuvandudzwa kwezvinodiwa zvekuchengetedzwa kwezvakatipoteredza, flue gasi desulfurization ye sintering furnace mumasimbi esimbi, sechinhu chakakosha chekutonga nyika mushure meiyo flue gasi desulfurization yemagetsi zvidyarwa, yakaverengera inosvika 11% yekubuda kwenyika kweSO2 uye zvimwe zvinosvibisa zvemuchadenga muindasitiri yesimbi, chinzvimbo chechipiri che2, CO2 chete kune iyo indasitiri yemagetsi, chinzvimbo chechipiri. uye zvimwe zvinosvibisa zvinogadzirwa mu sintering process account ye 40% ~ 60% yekubuda kwegore negore kwesimbi nesimbi indasitiri.Naizvozvo, zvakakosha zvikuru pakusimudzira kwakasimba kwesimbi nesimbi indasitiri uye kuvandudzwa kwemamiriro ekunze kudzora kubuda kwezvinosvibisa kubva kune sintering flue gasi uye kuita shanduko ye desunterfurization flue tekinoroji.

Ichitaura kune vanopfuura gumi vashandisi ve sintering flue gasi desulfurization process uye akawanda e desulfurization process dhizaini zvikamu zvakaita seShougang, Jinan, Baosteel neTangshan, kupfapfaidza kuomesa semi-yakaoma sintering flue gasi desulfurization process inoshandiswa zvakanyanya. Iyo yekupfapfaidza yekuomesa semi-yakaoma desulfurization maitiro ane hunhu hwehunyanzvi tekinoroji, kuyerera kwakapfava, kuvimbika kwakanyanya uye nezvimwe zvakadaro. The desulfurization rate inogona kusvika kupfuura 85%, SO2 emission concentration after desulfurization ≤100mg/Nm3, uye dust emission concentration ≤50mg/Nm3..Iyo nzira ine imwe application range (8%) muUnited States nedzimwe nyika dzekumadokero kweEurope.Desulfurized ash inogona kushandiswa se cement additive preparation, etc.

Mumakore achangopfuura, Wuxi Linzhou Drying Equipment Co., Ltd. yakaparura tsvakiridzo yekuvandudza gasi yeflue gasi desulfurization yemashini ekuisa mumashini esimbi neNanjing Forest Products Chemical Research Institute, Jinan Iron uye Steel Group, Dalian University yetekinoroji uye mamwe masangano:

Mukubatana neDalian University yeTekinoroji, chirimwa chekutyaira cheflue gasi desulfurization muchoto chinopisa chakavambwa muChongqing Iron uye Steel Group.

Iyo desulfurization tower dhizaini ye320m2 sintering muchina desulfurization chirongwa cheJinan iron uye simbi boka co., Ltd. uye bvunzo yemumba ye45-ton atomizing unit yakawana mhedzisiro yakanaka yekuchinja pakati pemidziyo yemumba nemidziyo inotengeswa kunze kwenyika.