Resource Kurapa kweBlack Liquor kubva Papermaking neSpray Drying

Sezvo akawanda ezvigadzirwa zvekudhonza muChina zvisiri zvehuni faibha mbishi (accounting inodarika 50%), alkali uye asidhi yekudzoreredza nzira dzinoshandiswa pakurapa doro dema mumapepa mazhinji. Nekudaro, nekuda kwekusaita kwemvura kusefa kwekuita kwehuswa huswa, masero akawanda akasiyana mudoro dema, yakakwira viscosity uye yakakwira silicon yedoro dema, iyo chaiyo mashandiro ekuita kwealkali kudzoreredza nzira haina kunaka, avhareji alkali recovery rate inosvika 60% chete, yakaderera kupisa kunyatsoshanda, mutengo wepamusoro wekushanda uye kutungamira kwakaoma. Naizvozvo, zvakaoma kugadzirisa zvachose dambudziko rekusvibiswa kwedoro dema mumashanga pulp plant. Pahwaro hwekutsvagisa nekuvandudzwa kwekupfapfaidza kuomeswa uye evaporation yemakore mazhinji, uye zvakasanganiswa nedhizaini uye ruzivo rwekushanda kwekuunza imwe chete system yekubuda uye kusungirirwa kwedoro dema munyika dzekunze, kambani yedu yakurudzira nekuita iyo zero kusvibisa kuburitsa maitiro ekurapwa kwedoro dema.

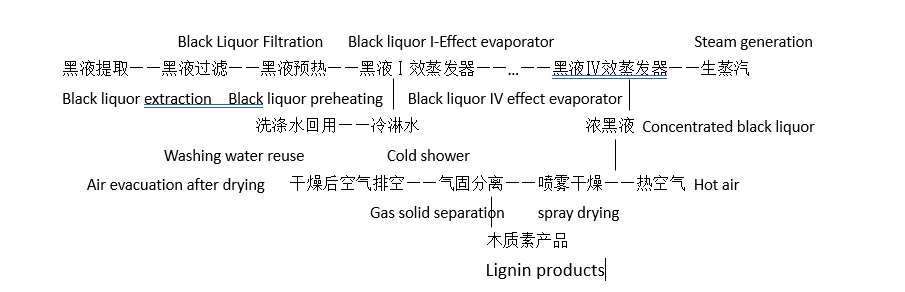

Mvura yakanyungudutswa nedoro dema rakanyungudutswa rinobuda muevaporator, condensate inogona kushandiswa semvura yekugeza, ukuwo doro dema rakanyura richipinda mukupfapfaidza. Munguva yekuomeswa kwekupfapfaidza, huwandu hweguruva hwakaburitswa kubva mukuomeswa system huri pasi pe100 ~ 150 mg / m3, iyo inogona kusangana neiyo nyika emission standard. Hapana tsvina yemvura inobviswa, uye zvigadzirwa zve lignin zvinowanikwa panguva imwe chete. Iyo yese maitiro ekurapwa kwedoro dema haina kunetsa kuwana, uye hapana gasi remarara uye tsvina yemvura inoraswa mukuita kwese, kuitira kuzadzisa chinangwa che zero kusvibiswa kuburitswa kwekubatwa kwedoro dema. Mapepa anogadzira doro dema anogadzirwa kuita lignin zvigadzirwa zvekushandisa zvakakwana. Inoshandiswa zvakanyanya mukongiri yemvura inoderedza, marasha emvura slurry dispersant, asphalt emulsifier, ceramics, oiri tsime kushandiswa kwekuwedzera, nezvimwe, kuitira kubvisa kukuvadzwa kwenzvimbo yezvakatipoteredza, kugadzira nharaunda-inoshamwaridzika, yakasikwa uye inowirirana mugwagwa webudiriro, uye kuona zvechokwadi kubatana kwehupfumi, mabhenefiti ezvakatipoteredza uye mabhenefiti munharaunda.

Zero discharge process yekuyerera kwedoro dema

1. Zvinyorwa:kugadzira mapepa doro dema nedoro dzvuku

2. Mhepo inopinza tembiricha:280 ℃ ~ 430 ℃

3. Tembiricha yekubuda kwemhepo:110 ℃

4. Dry powder kubuda:1000 kg / H ~ 4000kg / h

5. Solid content:40% ~ 50%

6. Nzvimbo yekupisa:yakananga yakadzingirwa marasha-inopisa inopisa blast stove ine kamuri yekugadzika, superheated steam, etc. (inogona kutsiviwa zvichienderana nemamiriro evatengi)

7. Atomization maitiro:high speed centrifugal atomizer inogamuchirwa

8. Nzira yekudziya:yakananga marasha-inopfuta inopisa blast stove (ine nhanho ina yekugadzika kamuri yekudzivirira zvinobudirira Mars kupinda)

9. Kudzoreredza zvinhu:Kubvisa guruva rekutanga cyclone uye yechipiri mvura yekugeza guruva kubviswa kunogamuchirwa, ine mwero wekudzoreredza we99.8%, unoenderana neyakajairwa Emission standards.

10. Kugamuchira:kugamuchirwa kwepakati kunogamuchirwa. Pazasi peshongwe uye hupfu hwakaburitswa kubva kudutu guruva muunganidzi zvinotumirwa zvakafanana kune iyo nemhepo yekugovera system Kurongedza kuchaitwa mudura reiyo yakasarudzika yekurongedza musangano.

11. Kudzora kwemagetsi:PLC chirongwa chekutonga chinogamuchirwa. (otomatiki kudzora tembiricha yemhepo inopinza, tembiricha yekubuda kwemhepo, tembiricha yemafuta uye kudzvanywa kweoiri alarm yeatomizer uye isina kunaka kuratidzwa kweshongwe)